Mahim, Mumbai, Maharashtra

- GST NO. : 27ADXPN7508A1ZA

| Business Type | Manufacturer, Supplier |

| GSM | 90 |

| Size | Coustomize, Customized |

| Color | White |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

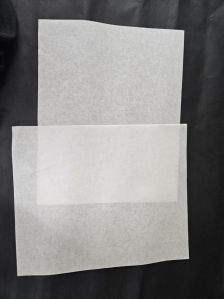

Printed Silicone 1 Side Coated Paper is a specialized paper product that features a silicone-coated side, making it ideal for applications requiring both printability and release properties. The silicone coating gives the paper its smooth, non-stick surface, which is essential in industries like packaging, food, medical, and electronics, where precise and clean release properties are necessary. The paper is one side coated with a silicone layer, while the other side remains untreated or lightly treated for printability. This makes it a versatile option for various printing techniques, such as flexographic or offset printing.

Specifications:-

Material Type:

- Base Paper: High-quality bleached kraft paper or similar substrates with strong structural integrity.

- Silicone Coating: Food-grade silicone or standard silicone coatings depending on the application.

-

Coating:

- Single-Side Coating: Silicone coating applied on one side only. The untreated side is suitable for printing.

- Coating Thickness: Typically ranges from 5 to 10 microns, depending on the intended use.

-

Weight:

- Paper Weight: Available in various weight ranges, commonly from 60 gsm (grams per square meter) to 150 gsm.

- Thickness: Can vary depending on paper weight but typically falls in the range of 0.05 to 0.2 mm.

-

Surface Finish:

- Silicone Side: Smooth and glossy, providing excellent release characteristics.

- Printed Side: Suitable for printing, usually with a matte or satin finish, depending on the paper grade.

-

Release Properties:

- Non-stick Surface: The silicone coating prevents adhesives, inks, and other substances from sticking to the paper.

- Low Coefficient of Friction: Ensures that products do not adhere to the coated surface, even in high-speed processing applications.

-

Printability:

- The untreated side is ideal for printing using flexographic, offset, or digital methods.

- Ink Compatibility: Compatible with a range of inks, including UV and water-based inks.

-

Temperature Resistance:

- High-Temperature Resistance: Suitable for applications that require heat resistance, such as in baking or food packaging.

- Silicone coatings can typically withstand temperatures ranging from -40°C to +200°C.

-

Applications:

- Packaging: Used for food packaging (such as baking sheets, wax paper alternatives), medical packaging, and product labels.

- Release Liner: Common in adhesive applications where the coated side acts as a release liner, preventing adhesives from sticking.

- Medical: Can be used in wound care products, surgical drapes, and other sterile applications.

- Electronics: Protects sensitive components during assembly, as well as in the manufacturing of flexible electronics.

-

Environmental Resistance:

- Moisture Resistance: Silicone coating provides moisture resistance, making it ideal for humid environments.

- Chemical Resistance: Resistant to most acids, alkalis, and solvents.

-

Environmental Considerations:

Looking for "Design Printed Silicone 1 Side Coated Paper" ?

Explore More Products