Mahim, Mumbai, Maharashtra

- GST NO. : 27ADXPN7508A1ZA

Silicon Coated Papers

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of Design Printed Silicone 1 Side Coated Paper, Hydrophlic White 180mm Napkin Realse Paper, logo printed coated 1 side 60gsm paper, Paper Bag Handle Rope paper, Printed Brown Hawana 1 Side Coated 60GSM, printed brown hawana coated 1 side paper, Release To Release Full Gum Transfer, Side Coated Paper, Uncoated Bcw Mgk Roll and Sheets, White Silicon 2 Side Coated Paper and Confetti Paper Blaster from Mumbai.

| Business Type | Manufacturer, Supplier |

| GSM | 90 |

| Size | Coustomize, Customized |

| Color | White |

| Material | Silicon Coated Paper |

| Brand Name | RK |

| Pulp Material | Mixed Pulp |

| Industrial Use | Packaging, |

| Product Code | 40R3 |

| Delivery Time | 5 DAYS |

| Packaging Details | Roll Off |

Preferred Buyer From

| Location | Worldwide |

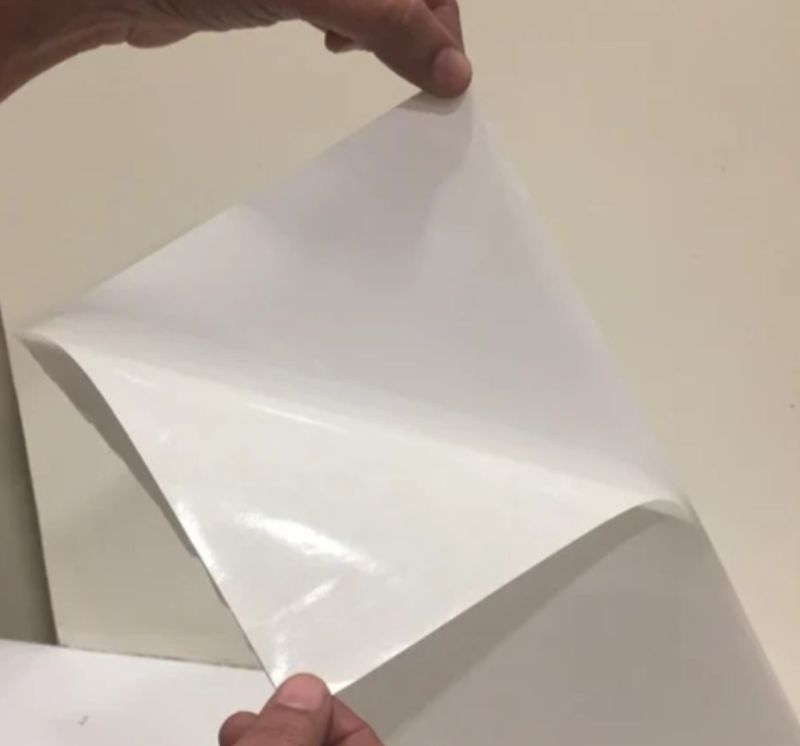

Printed Silicone 1 Side Coated Paper is a specialized paper product that features a silicone-coated side, making it ideal for applications requiring both printability and release properties. The silicone coating gives the paper its smooth, non-stick surface, which is essential in industries like packaging, food, medical, and electronics, where precise and clean release properties are necessary. The paper is one side coated with a silicone layer, while the other side remains untreated or lightly treated for printability. This makes it a versatile option for various printing techniques, such as flexographic or offset printing.

Specifications:-

Material Type:

- Base Paper: High-quality bleached kraft paper or similar substrates with strong structural integrity.

- Silicone Coating: Food-grade silicone or standard silicone coatings depending on the application.

-

Coating:

- Single-Side Coating: Silicone coating applied on one side only. The untreated side is suitable for printing.

- Coating Thickness: Typically ranges from 5 to 10 microns, depending on the intended use.

-

Weight:

- Paper Weight: Available in various weight ranges, commonly from 60 gsm (grams per square meter) to 150 gsm.

- Thickness: Can vary depending on paper weight but typically falls in the range of 0.05 to 0.2 mm.

-

Surface Finish:

- Silicone Side: Smooth and glossy, providing excellent release characteristics.

- Printed Side: Suitable for printing, usually with a matte or satin finish, depending on the paper grade.

-

Release Properties:

- Non-stick Surface: The silicone coating prevents adhesives, inks, and other substances from sticking to the paper.

- Low Coefficient of Friction: Ensures that products do not adhere to the coated surface, even in high-speed processing applications.

-

Printability:

- The untreated side is ideal for printing using flexographic, offset, or digital methods.

- Ink Compatibility: Compatible with a range of inks, including UV and water-based inks.

-

Temperature Resistance:

- High-Temperature Resistance: Suitable for applications that require heat resistance, such as in baking or food packaging.

- Silicone coatings can typically withstand temperatures ranging from -40°C to +200°C.

-

Applications:

- Packaging: Used for food packaging (such as baking sheets, wax paper alternatives), medical packaging, and product labels.

- Release Liner: Common in adhesive applications where the coated side acts as a release liner, preventing adhesives from sticking.

- Medical: Can be used in wound care products, surgical drapes, and other sterile applications.

- Electronics: Protects sensitive components during assembly, as well as in the manufacturing of flexible electronics.

-

Environmental Resistance:

- Moisture Resistance: Silicone coating provides moisture resistance, making it ideal for humid environments.

- Chemical Resistance: Resistant to most acids, alkalis, and solvents.

-

Environmental Considerations:

| Business Type | Manufacturer, Supplier |

| Brand Name | Amicare |

| Material | Paper |

| Color | White |

| Application | Labeling |

| Style | NA |

| Feature | Eco Friendly |

| Pattern | Plain, Printed |

| Type | Silicone Release Paper |

| Thickness | 3.5-4mm |

| Country of Origin | India |

| Length | 1200-1500mtr |

| Hardness | Soft |

| Transparency | Translucent |

| Delivery Time | 5 DAYS |

| Packaging Details | Roll OFF |

Preferred Buyer From

| Location | Worldwide |

Hydrophilic white 180mm napkin release paper is a specialized material used in the production of sanitary napkins. Its primary function is to protect the adhesive layer on the back of the napkin during storage and transportation, ensuring the adhesive remains clean and effective until use.

Description:

This release paper is typically made from high-quality paper or plastic film, treated with a release agent such as silicone oil. This treatment imparts low surface energy and anti-adhesive properties, allowing for easy removal without leaving residue. The standard size is 180mm in width, aligning with the dimensions of the sanitary napkin.

Specifications:

- Material: Paper or plastic film treated with silicone oil.

- Size: 180mm width, with lengths varying based on manufacturer specifications.

- Thickness: Typically around 40 micrometers (µm), though this can vary.

- GSM (Grams per Square Meter): Commonly 39 GSM, but may vary depending on manufacturer.

- Color: White.

- Features: Soft, breathable, and treated for easy release.

For instance, RK Enterprise offers a 39 GSM silicone-coated release paper with a width of 175mm, suitable for sanitary napkin back release applications.

For detailed specifications and to ensure compatibility with your production needs, it's advisable to consult directly with manufacturers or suppliers.

| Business Type | Manufacturer, Supplier |

| Design Service | Include / Exclude |

| Material | Paper |

| Type | Silicone Release Paper |

| Length | 100-400mtr |

| Application | Labeling |

| Colors | As per requirement |

| Pattern | Plain, Printed |

| Hardness | Soft |

| Transparency | Transparent |

| Country of Origin | India |

| Delivery Time | 5 DAYS |

| Packaging Details | Roll Off |

Preferred Buyer From

| Location | Worldwide |

Logo Printed Coated 1 Side 60 GSM Paper Specification and Description

Specification:

-

Weight:

- 60 GSM (Grams per Square Meter)

- This is considered a light weight paper, often used for promotional material, flyers, and brochures.

-

Coating:

- One-Sided Coating: The paper has a coating applied to only one side, providing a glossy or matte finish on that side. The uncoated side has a more natural, textured feel and is used for writing or printing minimal text.

- Gloss or Matte Finish: The coated side typically offers a glossy finish that enhances the color intensity of prints, making logos and images more vibrant.

-

Size:

- The paper can be provided in various standard sizes like A4, A3, Letter, etc., or customized as per the requirement.

-

Brightness:

- Typically high brightness (about 90-100 brightness level), which enhances print clarity and sharpness.

-

Printing Type:

- Suitable for Offset Printing and Digital Printing.

- Logo printing is commonly done on the coated side as the surface provides better ink adherence and vibrant colors.

-

Thickness:

- The thickness is generally thin due to the 60 GSM weight, giving it a light and flexible feel. It’s easy to handle and fold.

-

Application:

- Marketing Materials: Flyers, brochures, catalogs, promotional inserts.

- Packaging: Often used for lightweight packaging materials or promotional packages.

- Event Materials: Invitations, greeting cards, and other event materials.

-

Opacity:

- The opacity of 60 GSM paper is moderate, meaning it may have some transparency when held up to light, which is typical for lighter-weight paper.

-

Surface Finish:

- The surface is smooth and suitable for printing high-resolution images and logos. The glossy coating offers a shiny, reflective surface, while the matte coating results in a soft, non-reflective surface.

Description:

Logo Printed Coated 1 Side 60 GSM Paper is a high-quality, lightweight paper ideal for printing promotional and marketing materials. With a 60 GSM weight, this paper is perfect for creating flyers, brochures, posters, and catalogs that need a professional, polished appearance. The one-sided coating gives the paper a glossy or matte finish, which enhances the visual appeal of logos, text, and images on the printed side.

Due to its lightweight nature, it is easy to distribute and handle, making it a great choice for mass promotional campaigns. The smooth, coated surface allows for vibrant colors, sharp details, and rich contrasts, ensuring that logos and artwork stand out.

This type of paper is widely used in the printing industry for creating visually stunning marketing materials that require a balance of quality and cost-efficiency. The uncoated side offers some versatility for hand-written notes or additional printing, giving it a functional and adaptable nature for various printing needs.

Advantages:

- Affordable, high-quality printing material for cost-effective marketing solutions.

- Great for large runs of printed materials where vibrant visuals are a priority.

- Ideal for creating professional promotional materials that require a polished and clean finish.

| Business Type | Manufacturer, Supplier, Retailer, Trader, Distributor |

| Pattern | Plain, Printed |

| Feature | Easy Folding, Easy To Carry, Eco Friendly, Moisture Proof |

| Color | White |

| Application | Paper Bag Handle |

| Thickness | 2mm, 4mm |

| Style | Strip |

| Material | Kraft Paper, Paper, Papeer |

| Type | Paper Bag Handle Rope |

| Country of Origin | India |

| Brand | paper |

| Product Code | R8 |

| Port | MUMBAI |

| Payment Terms | T/T, Other |

| Delivery Time | 4 DAYS |

| Packaging Details | STRIP FOR MFG PAPER ROAP |

Preferred Buyer From

| Location | Worldwide |

paper strip roll

| Business Type | Manufacturer, Supplier |

| Brand Name | RK |

| Color | As Per Requirement |

| Design Printing | Printed |

| Application | Labeling |

| Size | A4 |

| Pattern | Printed |

| Type | Silicone Release Paper |

| Country of Origin | India |

| Material | Plastic |

| Thickness | 0.5-1mm |

| Length | 100-400mtr |

| Hardness | Soft |

| Transparency | Transparent |

| Delivery Time | 5 DAYS |

| Packaging Details | ROLL OFF |

Preferred Buyer From

| Location | Worldwide |

Printed Brown Hawana Coated One Side (C1S) paper is a specialized type of coated paper featuring a brown kraft paper base with a single-sided coating. This combination offers a unique aesthetic and functional properties suitable for various applications.

Description:

-

Base Material: The paper utilizes brown kraft paper, known for its strength and durability.

-

Coating: A coating is applied to one side, enhancing printability and providing a smooth surface for high-quality printing.

-

Finish: The coated side typically has a glossy or matte finish, depending on the specific requirements.

Specifications:

-

Grammage (GSM): Commonly available in the range of 50 to 100 GSM, offering a balance between strength and flexibility.

-

Dimensions: Available in various sizes, including standard industry sizes such as 23 x 36 inches (58.5 x 91 cm), 25 x 36 inches (63.5 x 91 cm), and 24 x 34 inches (61 x 86 cm). Custom sizes can also be produced upon request.

-

Packaging: Typically supplied in sheets or reels, with export-worthy packaging to ensure product integrity during transit.

Applications:

This type of paper is ideal for applications where the printed side is exposed, and the uncoated side is not visible. Common uses include:

-

Labels: Suitable for product labeling, especially when a rustic or natural appearance is desired.

-

Posters and Brochures: Ideal for promotional materials that require high-quality printing on one side.

-

Packaging: Used in packaging solutions where the exterior is printed, and the interior remains uncoated.

Features:

-

Enhanced Print Quality: The coating improves ink adhesion, resulting in vibrant and sharp prints.

-

Durability: The kraft base provides strength, making the paper suitable for products that require handling.

-

Eco-Friendly: Utilizing brown kraft paper contributes to sustainability, as it is often made from recycled materials.

| Business Type | Manufacturer, Supplier |

| Brand Name | RK |

| Color | As Per Requirement |

| Design Printing | Printed |

| Application | Labeling |

| Size | A4 |

| Pattern | Plain, Printed |

| Type | Silicone Release Paper |

| Country of Origin | India |

| Material | Paper |

| Thickness | 0.5-1mm |

| Hardness | Soft |

| Transparency | Translucent |

| Delivery Time | 5 DAYS |

| Packaging Details | Roll OFF |

Preferred Buyer From

| Location | Worldwide |

Printed Brown Hawana Coated One Side (C1S) paper is a specialized type of coated paper featuring a brown kraft paper base with a single-sided coating. This combination offers a unique aesthetic and functional properties suitable for various applications.

Description:

-

Base Material: The paper utilizes brown kraft paper, known for its strength and durability.

-

Coating: A coating is applied to one side, enhancing printability and providing a smooth surface for high-quality printing.

-

Finish: The coated side typically has a glossy or matte finish, depending on the specific requirements.

Specifications:

-

Grammage (GSM): Commonly available in the range of 50 to 100 GSM, offering a balance between strength and flexibility.

-

Dimensions: Available in various sizes, including standard industry sizes such as 23 x 36 inches (58.5 x 91 cm), 25 x 36 inches (63.5 x 91 cm), and 24 x 34 inches (61 x 86 cm). Custom sizes can also be produced upon request.

-

Packaging: Typically supplied in sheets or reels, with export-worthy packaging to ensure product integrity during transit.

Applications:

This type of paper is ideal for applications where the printed side is exposed, and the uncoated side is not visible. Common uses include:

-

Labels: Suitable for product labeling, especially when a rustic or natural appearance is desired.

-

Posters and Brochures: Ideal for promotional materials that require high-quality printing on one side.

-

Packaging: Used in packaging solutions where the exterior is printed, and the interior remains uncoated.

Features:

-

Enhanced Print Quality: The coating improves ink adhesion, resulting in vibrant and sharp prints.

-

Durability: The kraft base provides strength, making the paper suitable for products that require handling.

-

Eco-Friendly: Utilizing brown kraft paper contributes to sustainability, as it is often made from recycled materials.

| Business Type | Manufacturer, Supplier |

| Country of Origin | India |

| Other Names | NA |

| Feature | NA |

| Purity | NA |

| EINECS No. | NA |

| CAS No. | NA |

| Classification | NA |

| Application | Labeling |

| Brand Name | Amicare |

| Type | Silicone Release Paper |

| Material | Paper |

| Thickness | 0.5-1mm |

| Length | 1200-1500mtr |

| Color | As per requirement |

| Pattern | Plain, Printed |

| Hardness | Soft |

| Transparency | Translucent |

| Port | NA |

| Delivery Time | 5 DAYS |

| Packaging Details | Roll Off |

Preferred Buyer From

| Location | Worldwide |

A Release to Release Full Gum Transfer typically refers to a process used in dental or orthodontic procedures, where gum tissue is carefully transferred from one area of the mouth to another. The term “release” usually indicates a form of cutting or separating tissue (gums) to be repositioned or grafted, often as part of a grafting procedure. While there isn’t a universally recognized term for "Release to Release Full Gum Transfer," I’ll provide a general description and specification based on common dental and oral surgery terminology. If you're referring to something specific, like a particular dental technology or product, feel free to clarify! Description:A Release to Release Full Gum Transfer typically refers to a process used in dental or orthodontic procedures, where gum tissue is carefully transferred from one area of the mouth to another. The term “release” usually indicates a form of cutting or separating tissue (gums) to be repositioned or grafted, often as part of a grafting procedure. While there isn’t a universally recognized term for "Release to Release Full Gum Transfer," I’ll provide a general description and specification based on common dental and oral surgery terminology. If you're referring to something specific, like a particular dental technology or product, feel free to clarify! Description: A Release to Release Full Gum Transfer could involve the following elements in a dental context: Gum Tissue (Soft Tissue): The procedure may involve moving or grafting full thickness of the gum tissue (including the epithelium and underlying connective tissue) from one area of the mouth to another, often for the purposes of improving gum health, covering exposed roots, or enhancing the aesthetic appearance of the gums. Release Technique: The "release" aspect involves incisions made in the gum tissue to allow it to be freed up and repositioned. This could be done to facilitate better access or to create a space for grafting or transferring tissue. These incisions are typically made carefully to minimize scarring and optimize healing. Full Transfer: The full gum transfer means that the entire thickness of the gum tissue, as opposed to just the surface or part of it, is taken and repositioned. This is often necessary in cases where the gum tissue has been lost due to recession or injury and needs to be replaced by healthy tissue from another area of the mouth. Purpose: The goal of this procedure could be aesthetic restoration (covering exposed tooth roots), functional restoration (improving gum health), or protection (shielding vulnerable teeth or bone). Specifications: Materials Involved: Autografts (using the patient’s own gum tissue) or allografts (donor tissue) may be used. Sutures or special adhesives are used for securing the transferred tissue in place. Procedure Overview: Incision: A surgical incision is made around the gum tissue to be relocated. Gum Transfer: The gum tissue is carefully lifted and transferred to the desired location. Fixation: The gum tissue is then secured in place, typically with sutures, allowing it to heal and integrate into the new location. Healing Time: Healing can take several weeks, and the procedure is usually performed under local anesthesia or sedation. Post-surgery care includes maintaining oral hygiene, avoiding heavy physical exertion, and possibly applying antimicrobial treatments to avoid infection. Potential Applications: Gum Grafting: Often used in periodontal therapy to treat gum recession. Aesthetic and Functional Purposes: Enhancing the appearance of the gum line or repairing damaged gums. Risks and Complications: As with any surgical procedure, there may be risks such as infection, bleeding, or graft failure. There may be discomfort or pain during the recovery period, but this can typically be managed with medication and proper care. Postoperative Care: Pain management and monitoring for infection. Diet restrictions to avoid irritating t

| Business Type | Manufacturer, Supplier |

| GSM | 40 |

| Size | 2MM SIDE UNCOATED (20MM + 25MM + 30MM) |

| Product Code | 40R8 |

Preferred Buyer From

| Location | Worldwide |

| Business Type | Manufacturer, Supplier |

| Brand Name | RK |

| Pulp Material | PAPER |

| Shape | Square, Rectangular |

| Color | As Per Requirement |

| Application | Labeling |

| Type | Silicone Release Paper |

| Country of Origin | India |

| Material | Paper |

| Thickness | 0.5-1mm |

| Length | 100-400mtr, 1200-1500mtr |

| Pattern | Plain, Printed |

| Hardness | Soft |

| Transparency | Translucent |

| Delivery Time | 5 DAYS |

| Packaging Details | Roll OFF |

Preferred Buyer From

| Location | Worldwide |

Machine Glazed Kraft (MGK) paper is an uncoated, open-pored kraft paper that is smoothed on one side during production, resulting in a glossy finish on that side and a rougher texture on the other. This unique structure offers a combination of strength, smoothness, and porosity, making MGK paper suitable for various applications.

Specifications:

-

Basis Weight: Typically ranges from 45 to 65 grams per square meter (g/m²).

-

Coating: Single-sided coating is common; double-sided coating options are available.

-

Printing: MGK paper can be printed with back printing using one-color flexo printing.

Applications:

MGK paper is versatile and used in various industries, including:

-

Adhesive Tapes: Serves as a carrier material for adhesive tapes.

-

Graphic Applications: Employed in various graphic applications.

-

Medical Applications: Applicable in certain medical applications.

Read More...

-

| Business Type | Manufacturer, Supplier |

| Brand Name | RK |

| Material | Paper |

| Pulp Material | PAPER |

| Color | White, White |

| Design Printing | Printed |

| Application | PAPER TAPE |

| Feature | Long Strength |

| Country of Origin | India |

| GSM | 40 |

| Finshing | Non Printed |

| Logo | YES |

| Product Code | 40R4 |

| Size | Multisizes, Customized |

| Packaging Type | CUSTOM |

| Delivery Time | 5 DAYS |

| Packaging Details | Roll OFF |

Preferred Buyer From

| Location | Worldwide |

Silicone coated release paper imparts certain qualities to the paper including weight release, surface gloss, smoothness and reduced absorbency. The silicone coated release paper can then be used in food packaging, release paper and in magazines. However the coating formulation needs careful consideration for the chemical additives and dispersants being used. The coating can be carried out by adjusting the thickness of coating, speed of coating and the curing temperature. Silicone coated release paper coating comprises two-component and three-component systems for pressure sensitive tapes and labels.

Silicone coated release paper a range of silicones designed to be applied on one or both sides of a paper or film substrate. Also known as silicone coated release liners, they are used to protect sticky surfaces and to ease their handling. Silicone coated release paper are used in a wide array of markets and applications where it is critical to achieve a perfect coating to protect and deliver materials such as pressure sensitive adhesives (PSA) used in tapes and labels to their end destination. Beyond protection of self-adhesive or sticky materials they are also fantastic process aids and are used to enable casting and composite production processes and offer non-stick hygienic solutions for cooking and baking.

Silicone coated release liner paper has three different type of coating such as: Tin Coating, Platinum Coating and Glassine or Silicone Coating. We can provide Silicone coated release liner paper in custom size such roll and sheet form. The standard size for Silicone coated release liner paper is 20x30inch in sheet form and 20inch width in roll form. Our minimum order quantity for Silicone coated release liner paper is 200kg. Silicone coated release liner paper we have start from 40 to 120gsm.

| Business Type | Manufacturer, Supplier |

| Country of Origin | India |

| Type | Confetti Paper Blaster |

| Material | Paper |

| Shape | Round, Square |

| Application | party,wedding |

| Color | Multicoloured |

| Feature | Good Quality |

| Condition | New |

Preferred Buyer From

| Location | Worldwide |