Mahim, Mumbai, Maharashtra

- GST NO. : 27ADXPN7508A1ZA

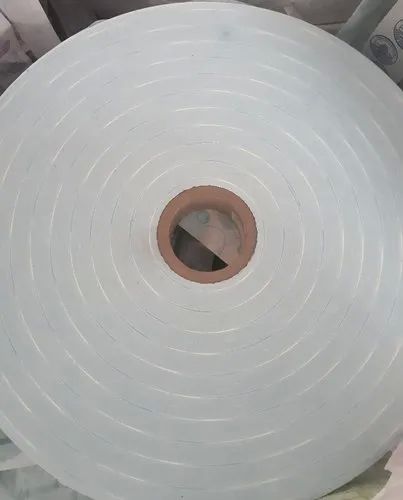

Silicone Paper Rolls

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of Brown Hawana coated Paper Roll, Logo Continue Printed Uncoated Paper, Name Printed Roll And Sheets, Pad Printed Uncoated Paper, White SIlicon 2 Side paper 90GSM, White Silicon One Side Coated 120GSM, White Uncoated Paper Roll And Sheet 40 Gsm and Zig Zag Adhesive Silicon Release Paper Roll from Mumbai.

| Business Type | Manufacturer, Supplier |

| Brand Name | RK |

| Color | Brown |

| Application | Wrapping |

| Industrial Use | NA |

| Feature | Antistatic, Greaseproof, Moisture Proof |

| Type | Corrugated Paper |

| Coating | Coated |

| Country of Origin | India |

| Size | Customised |

| Thickness | 0-5mm |

| Delivery Time | 5 DAYS |

| Packaging Details | Roll Off |

Preferred Buyer From

| Location | Worldwide |

Brown Hawana Uncoated Paper Roll refers to a type of uncoated paper commonly used for packaging, printing, and various industrial applications. The paper is typically brown in color, with a rough, uncoated texture that gives it a natural, earthy appearance. Below are the general specifications and description of this paper roll:

Specification:- Material: 100% Virgin Wood Pulp (sometimes a mix of recycled paper depending on the manufacturer).

- Weight (GSM): Generally available in a range of 40-150 GSM (grams per square meter). Heavier GSM paper is used for more robust packaging, while lighter weights are typically used for wrapping, printing, or lighter packaging.

- Width: The width of the paper roll varies depending on the intended application but typically ranges from 24 inches to 42 inches (610mm to 1067mm).

- Length: Lengths vary by roll size, with standard lengths being anywhere from 50 meters to several hundred meters.

- Color: Natural brown (often called kraft color).

- Surface Finish: Uncoated, meaning the paper has a rough, textured surface, suitable for writing, printing, or serving as packaging material. The texture may differ based on the specific grade or manufacturing process.

- Tensile Strength: High, ensuring durability and resistance to tearing, especially in heavier grades.

- Opacity: Moderate opacity, depending on the GSM. Thicker rolls tend to be more opaque.

- Moisture Content: Typically kept within an ideal range to prevent excessive brittleness or softness.

- Recyclability: Typically recyclable, as it’s made from paper pulp, and can be reused in the manufacturing of other paper products.

Brown Hawana Uncoated Paper Roll is often utilized in a variety of sectors due to its versatile properties. Some key uses include:

-

Packaging: This paper is commonly used for wrapping and packaging materials, especially in industries where a natural, eco-friendly look is desired. It provides a sturdy barrier for products and helps protect them during shipping and handling.

-

Printing: While not as smooth as coated papers, Brown Hawana uncoated paper is still suitable for certain printing applications like flyers, brochures, and other marketing materials where a rustic or eco-conscious aesthetic is preferred.

-

Food Industry: Some food packaging, particularly for bakery items and other goods that require natural wrapping, utilizes Brown Hawana Paper. It is durable and safe for direct contact with food.

-

Crafting and Stationery: Its rustic texture makes it popular for handmade crafts, art projects, and as a surface for writing, such as in notebooks or journals.

-

Environmental Appeal: The uncoated nature of the paper means that it retains a more natural, recyclable quality, which appeals to businesses and consumers focused on sustainability and eco-friendly products.

-

Durability: The uncoated surface often makes this paper highly durable for its weight, allowing it to resist wear and tear during storage, handling, and transport.

| Business Type | Manufacturer, Supplier |

| Brand Name | RK |

| Material | Paper,uncoated Paper |

| Pulp Material | PAPER |

| Color | White |

| Application | Labeling |

| Industrial Use | NA |

| Size | Coustomize |

| Certification | NA |

| Pattern | Plain |

| Type | Silicone Release Paper |

| Country of Origin | India |

| Thickness | 2.5-3mm |

| Length | 100-400mtr |

| Hardness | Soft |

| Delivery Time | 5 DAYS |

| Packaging Details | Roll OFF |

Preferred Buyer From

| Location | Worldwide |

Logo Continue Printed Uncoated Paper is a type of uncoated paper commonly used for continuous printing, particularly in businesses where high volumes of prints are required, such as invoices, forms, and other transactional materials. Here’s a description and the typical specifications for this paper:

Description:Logo Continue Printed Uncoated Paper is a durable, high-quality, non-glossy paper designed for continuous printing applications. It is often used in printers that require perforated sheets or continuous rolls to produce documents that may need to be torn off in sections. Its uncoated surface allows for excellent ink absorption, making it ideal for printing logos, text, and graphical designs without the shine that coated papers often have. This makes it suitable for official documents, promotional materials, and other print media where the paper quality needs to be practical, economical, and professional-looking.

Specifications:-

Paper Type: Uncoated

- The paper has a smooth, non-glossy surface.

- Often, this paper is produced using a natural wood pulp or recycled materials, ensuring a more sustainable product.

-

Brightness/Whiteness:

- Brightness typically ranges between 80–95% (depending on the manufacturer).

- The paper maintains a natural white or off-white shade, which helps maintain legibility.

-

Weight/Thickness:

- The paper is typically available in a variety of weights, most commonly from 60gsm (grams per square meter) to 120gsm.

- Heavier weights (e.g., 90gsm or 100gsm) are used for documents that require durability and a higher quality feel.

-

Surface Finish:

- Uncoated Finish: The surface is matte and natural, providing excellent ink absorption without any gloss or shine.

-

Size:

- Available in standard sizes such as A4, A3, and custom sizes for specific printing needs.

- Also available in continuous roll form for specific printing machines.

-

Printability:

- Compatible with a wide range of printing techniques including:

- Offset Printing

- Laser and Inkjet Printing

- Thermal Printing (in the case of continuous paper rolls)

- Flexographic Printing for mass production

- It is designed to provide crisp and clear print results, even for logos and fine details.

- Compatible with a wide range of printing techniques including:

-

Opacity:

- Good opacity, typically between 85-90%, ensuring minimal show-through of printed content from the opposite side.

-

Perforation:

- For continuous use in printers, the paper is often perforated along the edges or at intervals to allow easy tearing.

- This feature is commonly found in invoices, receipts, and other transactional print materials.

-

Environmental Considerations:

- The paper is often available in recycled versions and may carry certifications like FSC (Forest Stewardship Council), ensuring it’s sourced from responsibly managed forests.

- It is biodegradable and recyclable, making it an eco-friendly option compared to coated alternatives.

-

Applications:

- Transactional printing: invoices, bills, receipts, forms

- Direct mail printing for large-volume mailouts

- Promotional materials: catalog sheets, flyers

- Forms: continuous forms for data entry, questionnaires

- Cost-Effective: It is generally more affordable than coated papers, especially for high-volume printing.

- Professional Look: The uncoated finish provides a more natural, classic appearance that works well for official communications and documents.

- Ink Absorption: The paper absorbs ink better, resulting in a more matte finish without any glossy reflections.

This paper is a reliable option for companies that need to produce documents in bulk or on a continuous basis, while also providing sufficient quality for printing logos and graphics.

| Business Type | Manufacturer, Supplier |

| Material | Paper,Silicon Coated |

| Color | White |

| Application | Labeling |

| Length | 100-400mtr |

| Pattern | Plain, Printed |

| Type | Silicone Release Paper |

| Thickness | 2.5-3mm |

| Country of Origin | India |

| Hardness | Soft |

| Brand | RK |

| Size | Coustomize |

| Delivery Time | 5 DAYS |

| Packaging Details | Roll OFF |

Preferred Buyer From

| Location | Worldwide |

The term "Printed Roll and Sheets" generally refers to rolls or sheets of paper, film, or other substrates that have been printed with various designs, text, or graphics. These are typically used in industries like packaging, labels, textiles, and promotional materials. Below is a general specification and description for both printed rolls and printed sheets:

Printed Rolls:Description:

- Printed rolls are large rolls of material (paper, film, fabric, etc.) that are printed with designs, patterns, or text. They are commonly used for packaging (such as wrapping paper, gift wrap, or product labels), banners, and textiles. The material is generally wound onto a core to form a roll, which can be further processed or cut into smaller pieces.

Specifications:

- Material Type: Can be paper (kraft, glossy, matte), plastic film (PVC, polyester, polypropylene), fabric, or other substrates depending on the application.

- Roll Width: Varies depending on the intended use, commonly ranging from 12 inches to 60 inches (300mm to 1500mm).

- Roll Length: Can range from a few meters to hundreds of meters (depending on the type of material and the printing design). The roll length may be customized to order.

- Printing Method:

- Flexographic Printing: Used for large-scale commercial print runs (such as packaging).

- Gravure Printing: High-quality printing method used for fine details and large volumes.

- Digital Printing: For custom, on-demand prints, and smaller runs.

- Print Quality: High-resolution prints (up to 300 DPI or more) for clear, vibrant images and text.

- Ink Type: Water-based, UV-curable, or solvent-based inks depending on the substrate.

- Core Type: Paper or cardboard core, with various diameters (usually between 1.5" to 3").

- Finish: Glossy, matte, satin, or textured finish based on customer preference.

- Applications: Packaging (boxes, pouches, labels), wrapping paper, textiles, banner printing, and promotional materials.

Description:

- Printed sheets are individual cut pieces of material (typically paper or cardboard) that have been printed with text, images, or designs. These are generally used for products like flyers, brochures, business cards, posters, and custom packaging. Printed sheets are often cut to specific sizes for various uses.

Specifications:

- Material Type: Paper (coated or uncoated), card stock, vinyl, or other specialized materials.

- Sheet Size: Common sizes include standard (8.5" x 11", A4, A3) or custom dimensions.

- Weight: Paper weights are typically measured in GSM (grams per square meter) or pounds (lbs). Common weights include 80-100 GSM for regular printing, 200+ GSM for business cards, and up to 350 GSM for heavy-duty card stock.

- Printing Method:

- Offset Printing: High-volume printing with superior quality, suitable for large runs like brochures and flyers.

- Digital Printing: Suitable for small runs and custom jobs with quick turnaround times.

- Screen Printing: Used for specialty printing such as t-shirts, posters, and other promotional items.

- Ink Type: Standard ink (for offset or digital printing), UV inks, or specialty inks (metallic, fluorescent, etc.).

- Print Quality: Generally, sheets have high-resolution prints for detailed and vibrant colors, often with a minimum of 300 DPI.

- Finish: Glossy, matte, satin, or special coatings like UV coating, varnishing, or lamination.

- Cutting/Edges: Clean-cut edges (guillotine cutting, laser cutting, or die-cutting) for professional presentation.

- Applications: Flyers, brochures, business cards, posters, catalogs, custom packaging, and any printed material where individual sheets are required.

| Business Type | Manufacturer, Supplier |

| Brand Name | RK |

| Pulp Material | PAPER |

| Shape | Square |

| Color | White, Transparent |

| Application | Printing, Office, Labeling |

| Feature | Smooth Paper, Pulp Wood, Printing, Fine Finish |

| Type | Uncoated Paper, Silicone Release Paper |

| Country of Origin | India |

| Material | Paper |

| Thickness | 2.5-3mm |

| Length | 100-400mtr |

| Pattern | Plain |

| Hardness | Soft |

| Delivery Time | 5 DAYS |

Preferred Buyer From

| Location | Worldwide |

Pad printing on uncoated paper involves using a printing technique that transfers ink onto the paper surface using a silicone pad. This process is widely used for printing on irregularly shaped or difficult-to-print objects, and in this case, uncoated paper is the substrate being printed on.

Here is a typical specification and description for pad printed uncoated paper:

1. Material Description:- Type of Paper: Uncoated paper refers to a paper that does not have any glossy or smooth coating. It is typically more absorbent and has a matte or natural finish.

- Surface Texture: Rough, natural, and untreated. This texture can absorb ink well, but it might lead to slight bleeding of ink or reduced sharpness compared to coated surfaces.

- Thickness: Uncoated paper can vary in thickness, but it generally ranges from 70 gsm to 300 gsm depending on the printing and product requirements.

- Finish: Matte finish (uncoated). This provides a more natural, organic look and feel compared to glossy finishes.

- Pad Printing Description: A specialized printing technique in which ink is transferred from a printing plate to the substrate (paper) via a silicone pad. This process is ideal for printing on irregular surfaces, and it can handle small, detailed designs.

- Ink Type: Typically, solvent-based or UV curable inks are used in pad printing. For uncoated paper, inks need to be specifically formulated to adhere properly to absorbent surfaces and prevent smudging or fading.

- Absorbency: Because uncoated paper absorbs ink more than coated paper, the ink used must be optimized for this absorption, ensuring rich color saturation without excessive bleeding.

- Drying Time: The drying time on uncoated paper will be relatively quicker because the paper absorbs ink faster. However, depending on the ink type, additional curing (such as UV light) may be required for faster drying.

- Color Quality: Due to the absorbent nature of uncoated paper, colors may appear slightly muted or softer compared to their appearance on coated surfaces.

- Products: Ideal for products like stationery, envelopes, packaging (such as gift boxes or paper bags), labels, and promotional materials that require an organic and natural look.

- Usage: Commonly used for small-run printing jobs, where high-quality and detailed printing on irregularly shaped or rough-textured surfaces is necessary.

- Precision: Allows for fine details, such as logos, text, and designs to be transferred accurately.

- Versatility: Suitable for printing on non-flat surfaces or areas with a texture.

- Cost-Effective for Small Runs: Because pad printing does not require plates as expensive as those in offset printing, it's often used for small or medium runs.

- Ink Bleeding: Because of the absorbent nature of uncoated paper, ink can spread out beyond the intended print area, leading to reduced sharpness.

- Limited Durability: The print quality may not be as long-lasting as printing on coated paper, as uncoated paper can wear down more quickly.

- Resolution: Generally, pad printing allows for high-resolution prints, but the resolution may be affected by the absorbency of the paper. The detail may be slightly softer than on coated surfaces.

- Small text/Designs: Can be successfully printed, but the ink spread can cause slight fuzziness in very small fonts or intricate designs.

- Sustainability: Uncoated paper tends to be more environmentally friendly, as it usually contains fewer chemicals and is biodegradable.

Pad printing on uncoated paper provides a unique solution for printing on natural, textured materials, offering a more organic look and feel compared to coated paper. However, special attention must be paid to the type of ink used to ensure good adhesion and minimal bleeding.

| Business Type | Manufacturer, Supplier |

| Transparency | Translucent |

| Hardness | Soft |

| Pattern | Plain, Printed |

| Color | White |

| Application | Labeling |

| Length | 1200-1500mtr |

| Thickness | 2.5-3mm |

| Material | Paper |

| Type | Silicone Release Paper |

| Country of Origin | India |

| Delivery Time | 5 DAYS |

| Packaging Details | Roll OFF |

Preferred Buyer From

| Location | Worldwide |

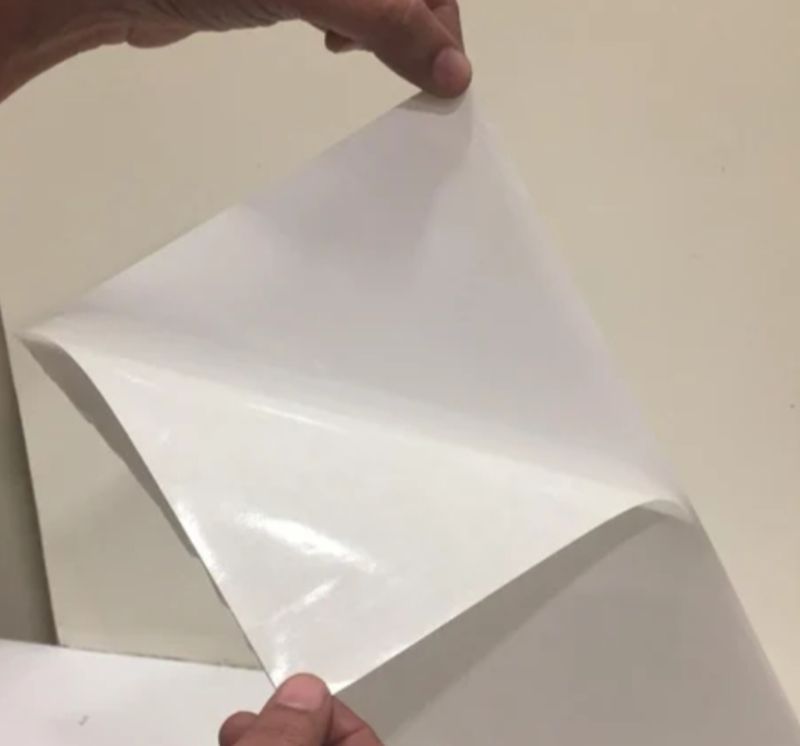

White Silicon 2 Side Coated Paper (often referred to as Silicone Coated Paper) is a type of paper that is coated with a silicone layer on both sides. This type of paper is commonly used for applications requiring a non-stick surface or for packaging and labeling in industries such as food packaging, medical, and cosmetics.

Specifications:-

Base Paper:

- Material: High-quality wood pulp or bleached chemical pulp

- Basis Weight: Typically ranges from 80 to 200 gsm (grams per square meter), but custom weights are also available.

- Thickness: Usually ranges from 0.08mm to 0.2mm, depending on the weight and application.

-

Silicone Coating:

- Coating Type: Both sides of the paper are coated with silicone (non-stick coating). The silicone acts as a barrier, preventing adhesives or other substances from sticking to the surface.

- Coating Weight: Typically ranges from 1.0 to 3.0 gsm per side, but this can be adjusted according to the required application.

- Silicone Quality: High-quality silicone coatings are used for better release properties.

-

Finish and Texture:

- Glossy or Matte Finish: The coating can provide either a glossy or matte finish depending on the specific requirements. The glossy finish enhances the appearance, while matte can reduce glare.

- Smooth Surface: The coated sides typically have a smooth and even surface, ideal for printing, die-cutting, and labeling.

- Opacity: It is generally opaque with some variation based on coating weight and base paper type.

-

Strength and Durability:

- Tensile Strength: Good tensile strength, ensuring that the paper does not tear easily when handling.

- Tear Resistance: Offers decent tear resistance, especially when used for applications such as baking sheets or release liners.

- Puncture Resistance: Puncture resistance is moderate to high depending on thickness and base paper quality.

-

Release Properties:

- Non-stick: The silicone coating gives it excellent release properties, preventing sticky substances, adhesives, or other coatings from bonding to the surface.

- Chemical Resistance: The silicone coating typically offers resistance to various chemicals, oils, and water.

-

Applications:

- Food Packaging: Commonly used as a liner in food packaging, such as for baking sheets, cookies, and other non-stick applications.

| Business Type | Manufacturer, Supplier |

| Hardness | Soft |

| Pattern | Plain, Printed |

| Color | White |

| Application | Labeling |

| Length | 1200-1500mtr |

| Thickness | 2.5-3mm |

| Material | Paper,Silicon Coated |

| Type | Silicone Release Paper,Paper |

| Country of Origin | India |

| Brand Name | RK |

| Delivery Time | 5 DAYS |

| Packaging Details | Roll OFF |

Preferred Buyer From

| Location | Worldwide |

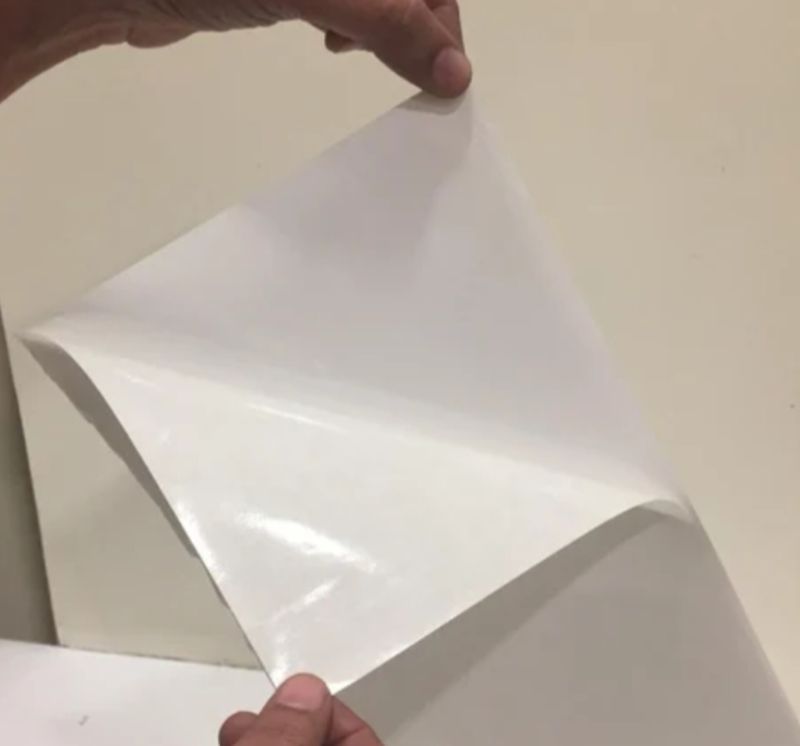

White Silicon One Side Coated 120 GSM refers to a type of paper or substrate with a specific coating and weight. Below is the detailed specification and description of this paper:

1. Weight:- 120 GSM (Grams per Square Meter): This indicates the thickness of the paper. The weight of 120 GSM paper is considered medium-thickness, commonly used for higher-end printing, packaging, and promotional materials.

- One Side Coated: This means that the paper is coated only on one side, while the other side remains uncoated or matte. Coated papers are generally smoother and provide a better finish for printing.

- The coating typically involves a layer of materials such as clay, which enhances the paper’s printability, brightness, and surface smoothness.

- This coating makes the paper more suitable for high-quality printing, providing sharper and more vibrant colors on the coated side.

- White: The paper has a clean, bright white appearance, ensuring clear and sharp text or images, ideal for printing purposes.

- Printing: The one-sided coating makes this paper perfect for printing high-quality images, text, or designs on the coated side. It’s often used for brochures, flyers, catalogs, posters, and packaging materials.

- Packaging: Because of its durability and smoothness, it’s also commonly used in high-end packaging, especially for retail products.

- Promotional Material: It’s a popular choice for marketing materials that need to convey a professional appearance with vivid colors and clear graphics.

- The coated side typically offers a glossy or semi-gloss finish, depending on the type of coating used. This enhances color reproduction and provides a more polished look.

- The uncoated side may have a more natural, matte finish, offering a contrast when used for text or other non-image content.

- Medium Durability: While 120 GSM paper is sturdy, it’s still lightweight enough for easy handling. However, it is not as durable as heavier-weight papers (such as 200-350 GSM), which are used for more rigid applications.

- Compatible with both Offset Printing and Digital Printing.

- The coated surface helps in providing superior quality prints, especially for images with rich colors and high detail.

- The environmental impact depends on the coating material used. Some coatings may contain chemicals, while others may be more eco-friendly. Look for specific brands that advertise sustainability or eco-friendly coatings if required.

White Silicon One Side Coated 120 GSM paper is ideal for high-quality printing tasks that require vivid color reproduction, smooth finishes, and durability, especially for promotional, marketing, or packaging purposes.

| Business Type | Manufacturer, Supplier |

| Size | Coustomize |

| Brand Name | RK |

| Material | Paper |

| Thickness | 2.5-3mm |

| Pattern | Plain, Printed |

| Color | White |

| Application | Labeling |

| Type | Silicone Release Paper |

| Country of Origin | India |

| Length | 100-400mtr |

| Hardness | Soft |

| Delivery Time | 5 DAYS |

| Packaging Details | Roll OFF |

Preferred Buyer From

| Location | Worldwide |

White Uncoated Paper Roll and Sheet - 40 GSM (Grams per Square Meter)

Specifications:-

Basis Weight (GSM):

40 GSM (Grams per Square Meter). This denotes the weight of the paper per square meter. -

Color:

White, providing a clean, bright surface for printing. -

Coating:

Uncoated, which means the paper has no surface coating or finish. This gives it a natural, matte texture and is ideal for absorbent ink or toner printing. -

Thickness:

Typically around 0.08 to 0.10 mm. (Thickness may vary slightly depending on the manufacturer and specific batch.) -

Brightness:

Around 90-95% ISO brightness (a measure of how reflective the paper is). Higher brightness gives a sharper, clearer image when printed. -

Opacity:

90%-95%. This indicates the paper's ability to prevent show-through of print from the opposite side. -

Smoothness:

Moderate smoothness, ideal for printing with minimal bleed or smudging. -

Size Options:

Available in roll form (widths can vary, commonly 800mm, 1000mm, or more) and cut sheet format (A4, A3, Letter, and custom sizes). -

Grain Direction:

Usually, the grain is aligned in the direction of the roll or the longer side of the sheet. This affects how the paper folds and handles in machines.

White uncoated paper with a basis weight of 40 GSM is a versatile, lightweight paper often used for everyday printing applications. Its uncoated nature makes it ideal for inkjet or laser printing, as it absorbs ink efficiently without excessive bleed-through.

This type of paper is often used for:

- Offset printing: It's commonly used in the printing industry for creating leaflets, flyers, brochures, and small books.

- Office use: Suitable for general-purpose printing in home or office settings, especially for documents, notes, or reports.

- Photocopying: It is perfect for photocopiers or printers that require a smooth, matte surface to ensure clear and crisp prints.

The 40 GSM weight ensures that the paper is light enough to be economical for bulk printing but still durable enough for everyday tasks. It is a more economical option than heavier papers, while still maintaining sufficient quality for most basic printing needs.

Because the paper is uncoated, it offers a more natural feel and is typically more environmentally friendly since it doesn't involve the use of synthetic coatings or finishes. However, it is less resistant to smudging, making it less ideal for high-end print jobs that require precision or gloss.

Applications:

- Commercial Printing: Such as flyers, pamphlets, and brochures.

- Packaging: Some lightweight packaging, like inserts or wrapping.

- Stationery: Includes letters, invoices, and everyday office papers.

It’s also a popular choice for printing educational materials, books, and newsletters due to its affordability and versatility.

| Business Type | Manufacturer, Supplier |

| Hardness | Soft |

| Pattern | Plain, Printed |

| Color | White |

| Application | Labeling |

| Length | 1200-1500mtr |

| Thickness | 2.5-3mm |

| Material | Paper,Na |

| Type | Silicone Release Paper,Na |

| Country of Origin | India |

| Brand Name | Amicare |

| Delivery Time | 5 DAYS |

| Packaging Details | Roll Off |

Preferred Buyer From

| Location | Worldwide |

Zig Zag Adhesive Silicon Release Paper Rolls are specialized materials designed to facilitate the easy removal of adhesives from surfaces. They are commonly used in applications such as sanitary napkin manufacturing, labeling, and other adhesive-related processes.

Specifications:

- Material: Paper coated with silicone on one side.

- Thickness: Typically around 2.5 to 3 mm.

- Length: Ranges from 1,200 to 1,500 meters per roll.

- Width: Commonly 175 mm, but custom sizes are available.

- GSM (Grams per Square Meter): Varies; for example, 40 GSM is standard for some applications.

- Adhesive Pattern: Zigzag line gum adhesive, often using hotmelt glue.

- Color: White, with options for custom printing.

- Coating: Silicone-coated on one side to ensure easy release of adhesives.

Description:

These release papers are engineered to provide a non-stick surface, allowing adhesives to be applied to the desired substrate without leaving residue. The silicone coating ensures that the adhesive can be removed cleanly and efficiently. The zigzag adhesive pattern is particularly suitable for applications like sanitary napkin back sheets, where controlled adhesive application is crucial.

Applications:

- Sanitary Napkin Manufacturing: Used as a release liner for hotmelt adhesives in the production of sanitary napkins.

For more detailed specifications or to place an order, you can contact manufacturers or suppliers such as RK Enterprise, which offers a variety of silicone-coated release papers tailored to specific applications.