Mahim, Mumbai, Maharashtra

- GST NO. : 27ADXPN7508A1ZA

Silicone Coated Release Paper Strips

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of Front Coated Back Side Register Printing Roll And Sheet, logo continue printed 1 side coated paper, name alphabet printed silicon 1 side coated paper, Twine Yarn Rope Paper Strip Roll and Uncoated Super Calander Kraft from Mumbai.

| Business Type | Manufacturer, Supplier |

| Brand | RK ENTERPRISE |

| Material | Coated Paper |

| Outer Material | Paper |

| Color | White |

| Feature | Waterproof,Reflective,Moisture Proof,Heat Resistant,Greaseproof |

| Type | Coated Paper |

| Country of Origin | India |

| Industrial Use | Packaging |

| Application | Food Packaging |

| Pattern | Plain |

| Delivery Time | 5 DAYS |

| Packaging Details | Roll OFF |

Preferred Buyer From

| Location | Worldwide |

Front Coated Back Side Register Printing Roll and Sheet refers to a specific type of paper or material used in printing that has certain coatings on one side and is designed for precise printing registration on both sides. Below is a description and typical specification breakdown for this product:

Description:-

Coating: The material is coated on the front side, often with a special layer that enhances the printability of ink, ensuring vibrant, sharp, and durable prints. The back side is usually uncoated or lightly treated to allow for proper adhesion or paper handling.

-

Purpose: The front coated back side register printing roll and sheet is designed specifically for high-quality, double-sided printing. It is used in applications where precision and color consistency are crucial, such as in high-end commercial printing, newspapers, and magazines, or for specialty print jobs.

-

Register Printing: This refers to the alignment of printing on both sides of the paper. Register printing ensures that the front and back sides of a printed sheet align perfectly, which is essential for multi-color printing where precision is required for overlapping images, text, or graphics.

-

Roll and Sheet Forms: It is available in both rolls and sheets, depending on the printing press requirements. Rolls are typically used for continuous printing operations, while sheets are more suited for cut-sheet presses.

-

Size (Sheet): Custom sizes are available, but standard sizes might include:

- A3 (297 mm × 420 mm)

- A4 (210 mm × 297 mm)

- B2 (500 mm × 700 mm)

- Other custom dimensions based on the customer’s requirement.

-

Size (Roll): The width and length of the roll can vary depending on the printer’s needs, often ranging from 300 mm to 1,500 mm in width, and a roll length of several hundred meters.

-

Basis Weight: This refers to the weight of the paper per unit of area, typically measured in grams per square meter (gsm). A common range for printing paper is:

- 90 gsm to 300 gsm for standard printing.

- Higher gsm (e.g., 350 gsm) is used for thicker, more durable stock for certain applications like covers, brochures, or packaging materials.

-

Coating: The front side is usually coated with a glossy or matte finish. The coating could be a:

- Gloss Coating: For high color saturation and shine.

- Matte Coating: For a more subdued, non-reflective finish.

-

Back Side: The back side may be uncoated or treated with a light coating to improve adhesion during printing while minimizing ink bleed or smudging.

-

Paper Type: Typically made of wood pulp, recycled material, or a blend of both. The quality of the pulp can impact the final print quality and durability of the material.

-

Opacity: High opacity is a typical feature, ensuring that printed images do not show through from the other side, which is important for double-sided printing.

-

Surface Finish: Depending on the finish of the coating, the paper can be either glossy, semi-gloss, or matte. The surface finish affects the absorption of ink, drying time, and the final visual quality.

-

Print Compatibility: Compatible with various printing technologies, including offset printing, digital printing, and flexography.

-

Durability and Handling: Designed to withstand handling, both during the printing process and post-printing stages (e.g., cutting, folding, binding). It is also resistant to fading and aging due to the coating and paper type used.

-

Environmental Certifications: Some papers may have eco-friendly certifications, such as FSC (Forest Stewardship Council), SFI (Sustainable Forestry Initiative), or PEFC (Programme for the Endorsement of Forest Certification).

-

Cost and Application: Premium papers with higher quality coatings may come at a higher cost but are ideal for high-end products, such as catalogs, magazines, marketing materials, and packaging.

| Business Type | Manufacturer, Supplier |

| Design Service | Include / Exclude |

| Printing Method | Digital Printing |

| Material | Paper |

| Colors | Full Color) |

| File Formats | |

| Size | 1. 40MM – 60MM (can get customize size) |

| Product Code | S1 |

| GSM | 40 |

| Delivery Time | 5 DAYS |

| Packaging Details | Roll OFF |

Preferred Buyer From

| Location | Worldwide |

When describing a "Continue Printed 1 Side Coated" logo, it generally refers to a printing specification for a material (like paper or cardboard) that has a coating on one side, used for printing logos, designs, and other graphics.

Here’s a breakdown of the specification and description for this type of printing:

Specification:-

Paper/Material Type:

- 1 Side Coated Paper: This means the paper or material has a coating (usually a glossy or matte finish) on only one side. The uncoated side may be left for writing or used for printing text or designs in a different style.

- Weight: The thickness or weight of the paper can vary, commonly ranging from 80-350 gsm (grams per square meter). A thicker paper weight might be chosen for durability or luxury feel.

-

Coating Type:

- Glossy or Matte Coating: The coated side can have either a glossy finish (shiny, reflective) or a matte finish (non-reflective, smooth). This is essential for achieving the desired visual effect for logos, especially for color depth and clarity.

-

Printing Method:

- Offset Printing: This is the most common printing method for high-quality results in large volumes. It ensures crisp, sharp details in the logo.

- Digital Printing: For smaller runs, digital printing is an option, offering faster turnaround times and a cost-effective choice.

-

Print Quality:

- The print resolution is typically high, ensuring the logo appears sharp and clear, especially if it has intricate details or fine lines.

- The coated side ensures color accuracy and vivid print quality, enhancing the appearance of your logo.

-

"Continue Printed" suggests that the logo or design will be printed on the material in such a way that it maintains a consistent visual identity, possibly extending across the material (e.g., a continuous design).

-

"1 Side Coated" means that the product being printed on has a coating on one side. The coated side is used for printing to create vivid colors and sharp details, while the uncoated side is either blank or used for non-printed content like text.

-

The coating enhances the durability of the print, making it more resistant to wear and tear, smudging, and fading, while also improving the overall aesthetics of the logo.

-

Usage: This type of material and printing setup is common for business cards, brochures, packaging, or promotional materials where the logo or design needs to stand out with high-quality print on one side.

| Business Type | Manufacturer, Supplier |

| Transparency | Translucent |

| Hardness | Soft |

| Pattern | Plain |

| Color | White |

| Application | Labeling |

| Length | 1200-1500mtr |

| Thickness | 0.5-1mm |

| Material | Paper,RK |

| Type | Silicone Release Paper,Silicon Coated |

| Country of Origin | India |

| Brand Name | RK |

| Delivery Time | 5 DAYS |

Preferred Buyer From

| Location | Worldwide |

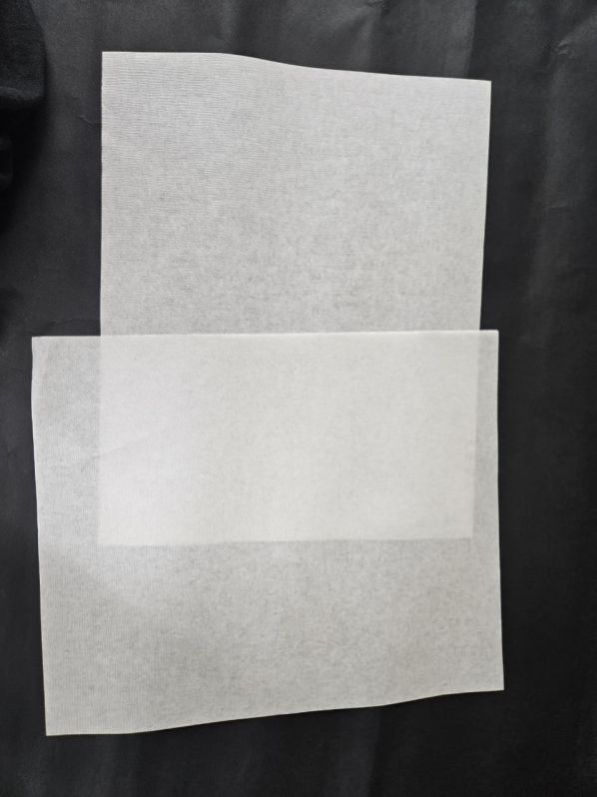

Alphabet Printed Silicon 1 Side Coated Paper is typically a specialized paper with a coating on one side, offering a smooth surface ideal for printing. The silicon coating often enhances the paper's durability and allows for easy printing of designs, especially those involving intricate patterns or fonts, like alphabet printing. Below are potential descriptions and specifications for this type of paper:

Description:Alphabet Printed Silicon 1 Side Coated Paper is a high-quality, specialized paper designed for printing precise alphabet designs and other custom graphics. It has a silicone-coated surface on one side, which makes it smoother and more receptive to ink or other printing techniques. The uncoated side provides a standard paper texture, offering some degree of texture and weight for various applications.

This paper is most commonly used for packaging, labeling, posters, or stationery that requires high print quality with sharp, clear alphabets and graphics. The silicon coating helps to prevent smudging and ensures vibrant colors on the printed side.

Specifications:- Material Composition: Typically made from wood pulp, with the addition of silicon coating on one side.

- Coating: One side is coated with a silicon layer, providing smoothness and printability.

- Surface Finish: Glossy or semi-gloss finish on the coated side; uncoated or matte texture on the other.

- Weight/Thickness: Paper weight can range from 80 gsm to 200 gsm, depending on the intended use (e.g., lightweight for brochures or heavier for packaging).

- Print Compatibility: Compatible with offset printing, screen printing, flexographic printing, and digital printing, depending on the paper's weight and coating quality.

- Opacity: Moderate to high opacity to prevent ink bleed-through.

- Color: Typically available in white, though custom colors are also possible.

- Durability: Resistant to tearing, creasing, and fading; the silicone coating enhances the paper’s resistance to moisture and other environmental factors.

- Applications:

- Packaging

- Labels and Stickers

- Greeting Cards

- Flyers

- Posters

- Stationery

- Invitations

- Environmental Impact: Depending on the manufacturer, may be eco-friendly (e.g., recyclable or biodegradable) or treated with chemicals for enhanced durability.

| Business Type | Manufacturer, Supplier |

| Country of Origin | India |

| Type | Paper Strip Roll |

| Material | Paper |

| Pattern | Plain |

| Technics | Machine Made |

| Color | As per requirement |

| Oxidation Resistance | Yes |

| Size | 5-10mm |

| Packaging Type | Roll |

Preferred Buyer From

| Location | Worldwide |

| Business Type | Manufacturer, Supplier |

| Material | Paper |

| Color | White |

| Usage/Application | Gifts,Envelope Pested |

| Country of Origin | India |

| Type | Paper Rolls |

| Certification | ISO 9001:2008 |

| Feature | Premium Quality, Moisture Proof, Fine Finish, Eco Friendly |

| Pattern | Plain |

| Width | 6inch |

| GSM | 50-100gsm |

| Delivery Time | 5 DAYS |

Preferred Buyer From

| Location | Worldwide |

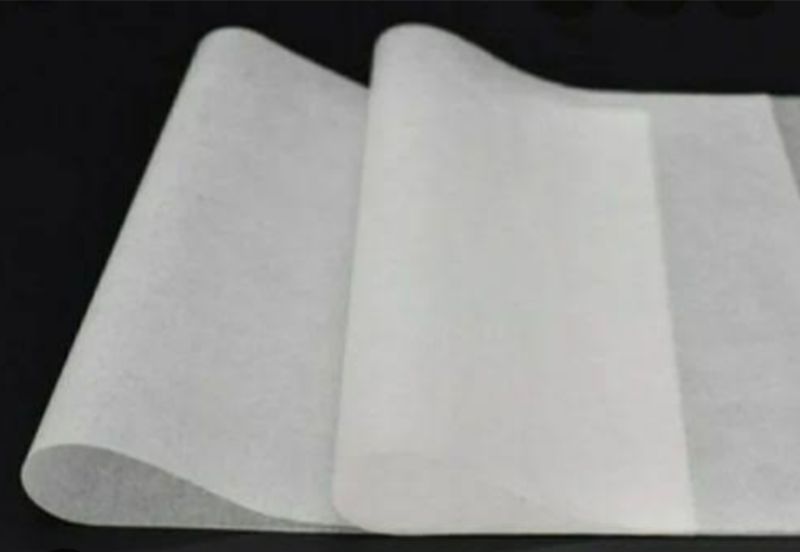

Uncoated Super Calendered Kraft Paper (SC Kraft Paper) is a type of kraft paper that has undergone a calendering process to enhance its smoothness and finish. It is typically made from virgin wood pulp, which gives it strength, durability, and versatility for a wide range of uses. The uncoated nature of the paper means it retains its natural texture and absorbency.

Key Characteristics & Specifications:-

Material Composition:

- Made from virgin or recycled wood pulp.

- Strong, durable, and tear-resistant due to the kraft pulping process.

-

Calendering Process:

- After being manufactured, the paper goes through a calendering machine, where it is pressed between heated rollers. This process increases smoothness and density without adding a coating.

-

Surface Finish:

- Smooth but uncoated: The paper has a slightly glossy finish due to calendering but does not have a coating layer like other types of paper (e.g., coated paper).

- Natural texture: Retains a natural, rustic look and feel.

-

Color:

- Typically a light brown to dark brown color depending on the pulp used and the production process.

- Can be available in bleached (lighter color) or unbleached (darker color) variations.

-

Strength:

- High tensile strength: It is resistant to tearing and has high durability, making it ideal for applications requiring rugged material.

- Bursting strength: The paper can withstand a significant amount of pressure before tearing or bursting.

-

Weight & Thickness:

- Available in a wide range of grammages (from 30 gsm to 250 gsm or more).

- The thickness can vary depending on the weight of the paper.

-

Opacity:

- Moderate opacity: The paper is somewhat opaque but may allow slight visibility through the paper depending on the weight.

-

Applications:

- Packaging: Frequently used for kraft paper bags, envelopes, and wrapping.

- Printing & labeling: Suitable for flexographic printing, but due to its uncoated nature, high-resolution printing may have a more textured finish.

- Food packaging: Often used for food-grade packaging applications (with a natural appearance and safe for direct contact with food).

- Envelopes and Mailing: Often used for premium envelopes, especially for industrial and high-end uses.

-

Environmental Impact:

- Recyclable and biodegradable: SC kraft paper is environmentally friendly due to its natural composition, making it a sustainable choice for many industries.

- Low environmental footprint: The uncoated nature of the paper contributes to a lower impact on the environment compared to highly processed papers.

- Strength & Durability: The paper is stronger than many other uncoated papers, making it ideal for packaging and industrial uses.

- Eco-friendly: Being recyclable and biodegradable, it is a more sustainable option compared to synthetic materials.

- Versatility: Can be used in a wide range of applications from food packaging to industrial uses, printing, and retail.

- Natural Look & Feel: Its rustic and natural appearance is preferred for certain branding and packaging needs.

- Limited Print Quality: Since it’s uncoated, the print quality may not be as sharp or vibrant as coated papers, though it’s still suitable for most industrial printing needs.

- Water Resistance: Although durable, it can absorb moisture, leading to a loss of strength in highly humid conditions unless treated for moisture resistance.