Mahim, Mumbai, Maharashtra

- GST NO. : 27ADXPN7508A1ZA

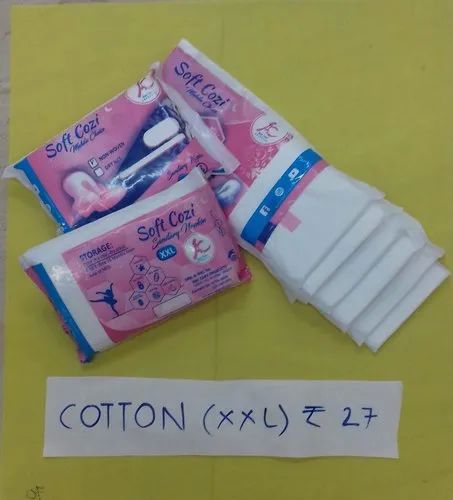

Sanitary Napkins

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of B Grade Cotton Sanitary Napkin, Release paper Sheet And Roll and Silicon Coated Paper Release Paper Strip from Mumbai.

| Business Type | Manufacturer, Supplier |

| Country of Origin | India |

| Size | XXL |

| Type | Panty Liner |

| Material | Cotton |

| Shape | Winged |

| Style | Disposable |

| Feature | Breathable, Fan-Shape, Odor Control, Side Gather |

| Brand Name | Soft Cozi |

Preferred Buyer From

| Location | Worldwide |

| Business Type | Manufacturer, Supplier |

| Brand Name | Amicare |

| Material | Cotton,Paper |

| Pulp Material | PAPER |

| Color | White |

| Design Printing | Printed |

| Length | 100-400mtr |

| Feature | Breathable, Fan-Shape, Odor Control, Side Gather |

| Type | Woman Sanitary Napkin,Panty Liner |

| Country of Origin | India |

| Size | L, XL |

| Shape | Folded, Winged |

| Style | Disposable |

| Time Used | Day, Night, One Time Use, Any Time |

| Product Code | S2 |

| Port | Transport |

| Delivery Time | one week |

| Packaging Details | Customised Packaging |

Preferred Buyer From

| Location | Worldwide |

The specifications and description of release paper (often referred to as release liner or release film) vary depending on the specific requirements for its application, such as the industry (adhesives, automotive, packaging, etc.) and the materials being used. However, here’s a general outline of common specifications and descriptions for release paper sheet and roll:

1. Material Composition:- Base Paper:

- Usually made from kraft paper, bond paper, or film (like PET or polypropylene).

- It can be either coated or uncoated, with coating often applied to ensure the release properties.

- Release Coating:

- The release coating is typically made from silicone or fluoropolymer materials that provide a non-stick surface.

- The release layer can be single-sided (only on one side) or double-sided depending on the need.

- Paper Thickness:

- Ranges from 30 gsm to 300 gsm for sheets. For rolls, the thickness might range from 0.025 mm to 0.1 mm or higher.

- The thickness can vary depending on the weight and rigidity required for the application.

- Coating Thickness:

- Release coating typically ranges from 0.5 microns to 3 microns, depending on the level of release needed.

- Sheet Dimensions:

- Standard sizes can be A4 (210 x 297 mm), A3 (297 x 420 mm), or custom sizes.

- Roll Dimensions:

- Roll width: Can range from 100 mm to 3000 mm (4” to 118”).

- Core Diameter: Typically, the core diameter can be 3” or 6”, though custom sizes may be available.

- Roll Length: Can vary from 100 m to 1000 m or more, depending on the application.

- Release Force:

- The release force, which is the strength required to peel the paper away from an adhesive or product, varies and can be controlled by adjusting the type and amount of coating applied.

- It can range from low release (light adhesion) to high release (strong adhesion).

- Surface Finish:

- Release paper can be glossy, matte, or satin, depending on the desired visual effect or the sensitivity of the material being applied.

- Tensile Strength:

- Release papers often have good tensile strength to prevent tearing during the application process.

- Moisture Resistance:

- High-quality release papers are often treated to be moisture-resistant or waterproof to prevent the paper from getting damaged during handling or application.

- Adhesive Products: Release papers are primarily used for products like pressure-sensitive adhesives, tapes, labels, and stickers.

- Medical and Hygiene Products: Used as liners for diapers, sanitary pads, and wound dressings.

- Industrial Applications: Used in applications like vinyl wraps, lamination, or electronics assembly where the removal of protective layers is required.

- Automotive and Packaging Industries: Also used in specialized packaging and protective films.

- Antistatic Properties: Some release papers are treated to be antistatic to prevent static buildup, especially in sensitive applications like electronics.

- Food Safety: Release papers used for food packaging may be treated to meet food safety regulations.

- Eco-Friendly Options: Some release papers are designed to be more environmentally friendly, using sustainable paper and coatings.

- Release paper can be printed on or customized with logos, branding, or specific instructions for the end user.

| Material | Kraft paper, PET film, etc. |

| Coating | Silicone, fluoropolymer |

| Thickness (Paper) | 30 gsm - 300 gsm |

| Thickness (Coating) | 0.5 - 3 microns |

| Release Force | Light to strong release |

| Width (Roll) | 100 mm - 3000 mm |

| Length (Roll) | 100 m - 1000 m |

| Surface Finish | Glossy, Matte, Satin |

| Core Size | 3” or 6” |

| Tensile Strength | Medium to high |

Release paper sheets and rolls are specialized products designed to provide a n

| Business Type | Manufacturer, Supplier |

| Brand Name | Amicare |

| Material | Paper, Cotton |

| Pulp Material | PAPER |

| Color | White |

| Design Printing | Printed |

| Feature | Breathable, Fan-Shape, Odor Control, Side Gather, Super Absorbent |

| Type | Woman Sanitary Napkin,Panty Liner |

| Country of Origin | India |

| Size | L, XL |

| Shape | Folded, Winged |

| Style | Disposable |

| Time Used | Day, Night, One Time Use, Any Time |

| Product Code | S1 |

| Port | Transport |

| Delivery Time | one week |

| Packaging Details | Customised Packaging |

Preferred Buyer From

| Location | Worldwide |

Silicon-coated paper release paper, also referred to as silicone release paper or silicone paper, is a specialized paper treated with a silicone coating. This treatment gives the paper its unique non-stick and release properties, making it ideal for a variety of applications where a clean, easy separation is necessary. The paper is widely used in industries like adhesives, labeling, medical, and packaging, where a protective layer needs to be peeled off with ease. Description: Silicon-coated paper is primarily used as a release liner for adhesive products. The silicone layer makes it easy to peel off without leaving residues or damaging the product underneath. It is available in different weights, thicknesses, and textures, allowing for customization depending on the specific requirements of the application. Applications: Adhesive Products: Used in pressure-sensitive labels, stickers, tapes, and medical bandages. Labeling: As a backing for self-adhesive labels and stickers. Packaging: Protects sticky surfaces during manufacturing or transport. Electronics: Protects delicate surfaces like screens during shipping or assembly. Medical: Can be used in wound dressings or in the production of medical tape. Specification: Material Composition: Base Paper: Usually made from wood pulp or Kraft paper, which is known for its strength and durability. Silicone Coating: One or both sides of the paper are coated with a thin layer of silicone, which is what gives it the release properties. The coating could be of varying thickness depending on the application. Weight and Thickness: Paper weight typically ranges from 40 gsm to 150 gsm. Thickness of the paper typically ranges from 0.05mm to 0.15mm (depending on the base paper and the silicone coating thickness). The thickness and weight will affect the rigidity, strength, and flexibility of the paper. Release Properties: Release Force: Typically, the release force (the force needed to peel the paper off the adhesive surface) is calibrated to specific needs. It could range from light (for products like stickers) to high (for heavy-duty tapes). Silicone Coating Types: There are different grades of silicone coatings, such as high-performance, medium-performance, and light-duty. The type of silicone used affects the smoothness and release efficiency. Surface Characteristics: The surface can be smooth or textured, depending on the required use. It can be treated to have a glossy or matte finish. Roll Dimensions: Common roll widths range from 300 mm to 1200 mm, though they can be custom-made. Roll lengths vary, commonly between 100 meters to 500 meters depending on the specific application. Color: The paper is generally white or off-white, though it can be customized to other colors, depending on the requirements (for example, for branding or specific uses in the medical or electronics industry). Durability: Silicon-coated paper is generally durable and resistant to heat, moisture, and chemical exposure, though the exact durability will depend on the paper's grade and intended use. Adhesive Compatibility: Works well with various adhesive types such as acrylic, rubber-based, and silicone adhesives. It’s designed to offer a smooth release for pressure-sensitive adhesives. Environmental Considerations: Generally, silicon-coated papers are not recyclable due to the silicone layer. However, environmentally friendly versions are available, made from recycled paper or biodegradable silicones. Additional Customizations: Perforations: The release paper may come with perforations, allowing it to be torn or cut easily for specific applications. Anti-static: Some versions are treated to be anti-static, especially for use in electronics and other sensitive products. Liner for Flexible Films: Often used as a liner for flexible films in the manufacturing of flexible products. In summary, silicon-coated paper release paper is an essential material in many industries that req