Mahim, Mumbai, Maharashtra

- GST NO. : 27ADXPN7508A1ZA

| Business Type | Manufacturer, Supplier |

| Type | Ancona |

| Gender | Female |

| Age | 6 Months |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

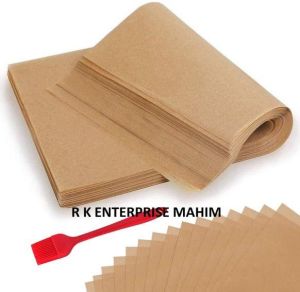

Medical Grade PE White Back Layer: Description and Specifications

A Medical Grade PE (Polyethylene) White Back Layer is a specialized material used in various medical applications, particularly in wound care, dressings, medical packaging, and as a protective layer in medical devices. The material offers several features that make it ideal for use in medical environments where cleanliness, protection, and comfort are essential.

Description:- Material: Polyethylene (PE), a durable, flexible thermoplastic polymer that is widely used in medical devices and packaging due to its chemical resistance, biocompatibility, and low moisture absorption.

- Color: White, which is typically preferred in medical settings for cleanliness and the ability to clearly view any signs of contamination.

- Back Layer Function: The white back layer typically serves as a protective outer layer in various medical products, offering a barrier to external contaminants while providing a smooth surface for patient contact.

-

Material Type:

- Polyethylene (PE), medical-grade with appropriate certifications (such as ISO 10993 for biocompatibility).

-

Thickness:

- Typically ranges from 0.03 mm to 0.10 mm, depending on the application. For example, thinner layers are often used for medical dressings, while thicker versions may be used in protective packaging.

-

Tensile Strength:

- The material has a high tensile strength, providing durability without compromising flexibility.

-

Elasticity/Flexibility:

- PE is highly flexible, making it suitable for products that need to conform to body contours or be used in products that require movement.

-

Biocompatibility:

- Medical-grade PE is non-reactive with human skin and tissues, ensuring it can be safely used in direct contact with patients, particularly in dressings, bandages, or surgical kits.

-

Water Resistance:

- Polyethylene is water-resistant, providing an effective barrier against moisture, which is crucial in many medical applications.

-

Barrier Properties:

- Acts as a physical barrier to bacteria and external contaminants, preventing contamination in medical products.

-

Temperature Resistance:

- PE can withstand a wide range of temperatures, making it suitable for both sterilization and medical storage conditions.

-

Opacity/Transparency:

- Generally, PE used in medical products is opaque or slightly translucent, which is suitable for visibility during medical inspections without compromising sterility.

-

Sterilization Compatibility:

- Can typically be sterilized using methods like gamma radiation, ethylene oxide (EO) gas, or steam (depending on the product design and thickness).

-

Durability and Strength:

- PE offers high durability while remaining lightweight, contributing to the overall strength and functionality of the final medical product.

-

Applications:

- Medical Packaging: Packaging for sterile medical instruments and devices.

- Wound Care: Protective layer in wound dressings.

- Surgical Applications: Used in surgical drapes and gowns as a protective layer.

- Sterile Barrier Systems: Common in sterile packaging for pharmaceuticals or medical kits.

- Safety: Prevents contamination by offering a barrier to pathogens and moisture.

- Comfort: The flexibility and softness provide comfort in medical dressings.

- Reliability: Medical-grade PE maintains its integrity under various environmental conditions, ensuring performance.

- Ease of Use: Its pliability and low weight make it easy to incorporate into medical applications.

Medical Grade PE White Back Layers are versatile, durable, and reliable materials used in a wide variety of medical products, providing essential protection while maintaining patient safety and comfort.

Looking for "Medical Grade Pe White Back Layer" ?

Explore More Products